The Cost of Quality – A Solar IE’s perspective

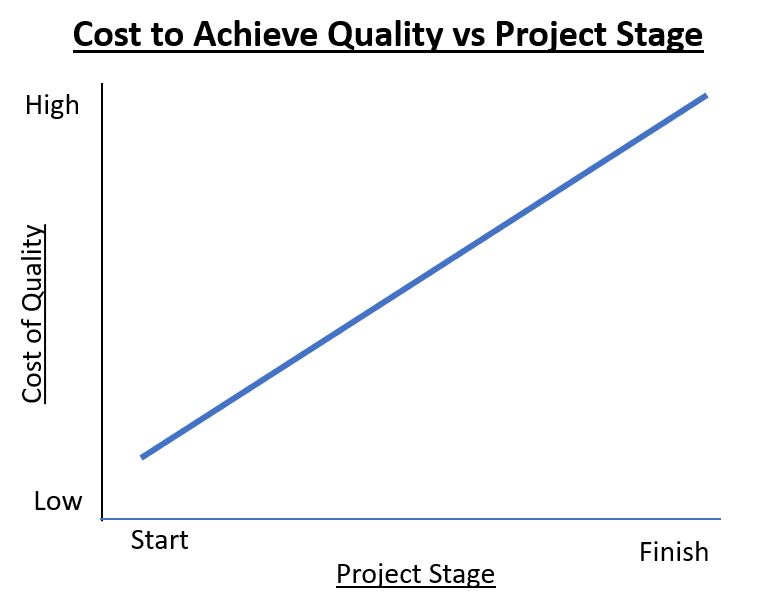

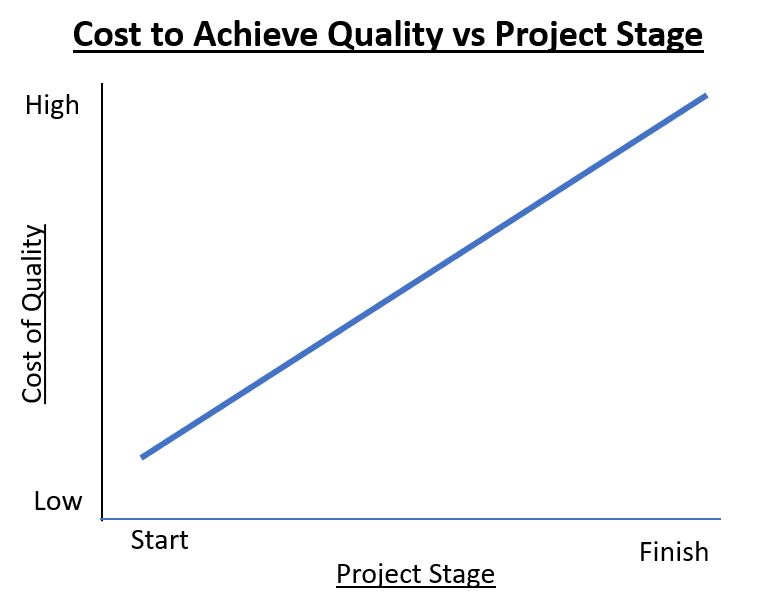

There's a well-known business principle known as the "Cost of Quality." It essentially states that the closer a project gets to completion, the more expensive it becomes to address quality issues. This concept highlights how early detection and correction of problems can save time, money, and effort down the line.

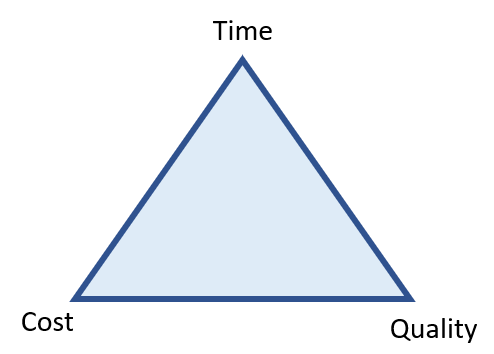

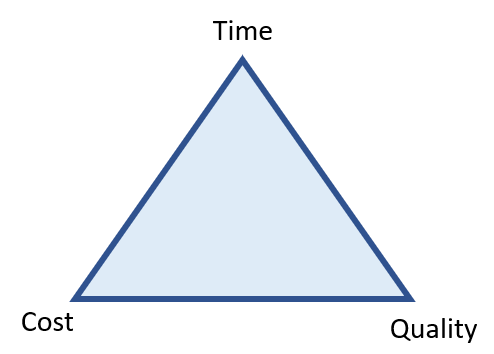

Quality in projects is often measured in terms of Time (schedule) and Cost ($$$). Project Management literature refers to these as the “triple constraints,†typically illustrated by the classic triangle:

Quality in projects is often measured in terms of Time (schedule) and Cost ($$$). Project Management literature refers to these as the “triple constraints,†typically illustrated by the classic triangle:

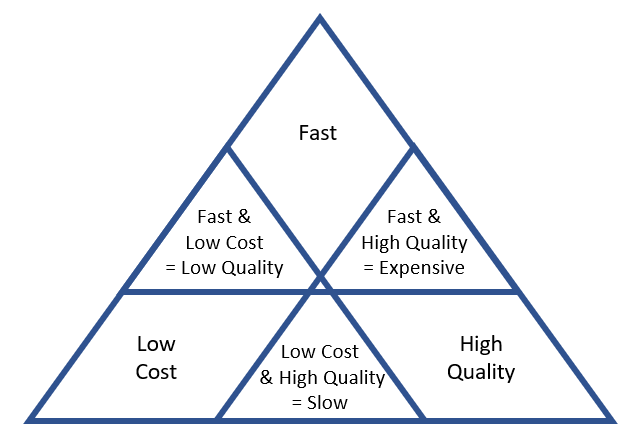

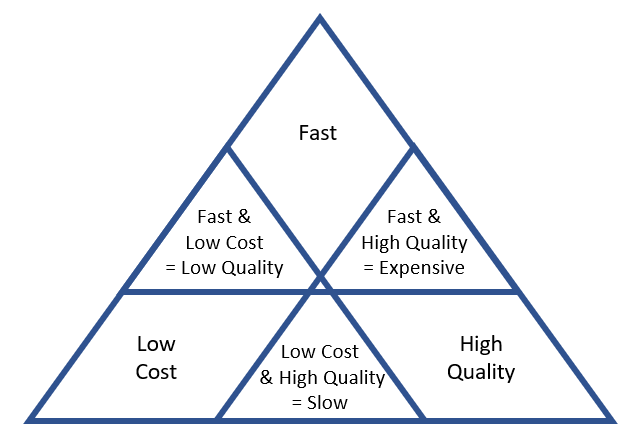

The idea is that you can optimize two of the three constraints but must compromise on the third. In solar projects, this balance between time, cost, and quality is especially critical during design and construction.

The idea is that you can optimize two of the three constraints but must compromise on the third. In solar projects, this balance between time, cost, and quality is especially critical during design and construction.

As an Independent Engineer (IE), we always aim to preserve quality throughout the project lifecycle. However, when reviews are conducted too late—often at the end of installation—fixing quality issues becomes significantly more costly and time-consuming.

### The Problem with Late IE Reviews

Developers often bring in engineers late in the project to satisfy owners or lenders who want to de-risk the project. This final review is usually done just before handover, as a last check on design and installation.

At this stage, addressing quality issues requires significant changes, which can impact both time and budget. By the time a problem is discovered, many key steps have already been completed:

- Design is finalized

- Materials are procured and installed

- Labor has been expended

- Performance guarantees are set in contracts

This means any corrections will likely lead to delays, increased costs, or suboptimal solutions.

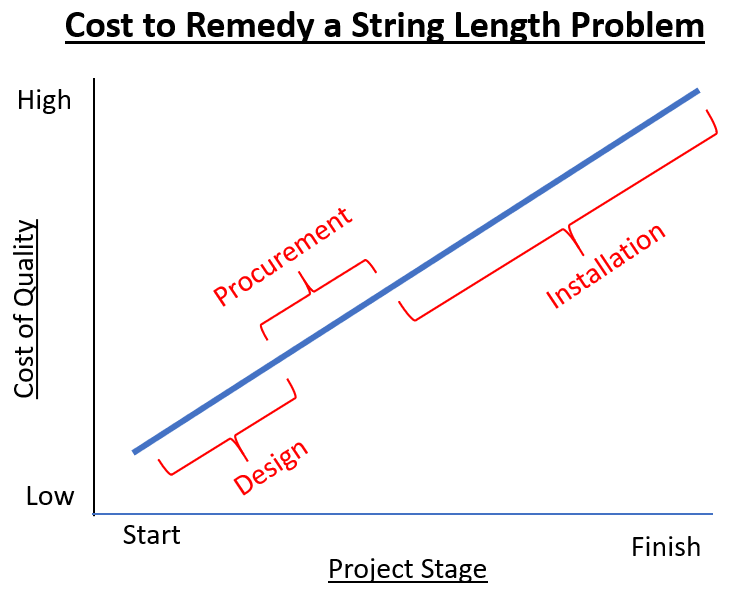

### Example of the Cost of Quality: String Length Miscalculation

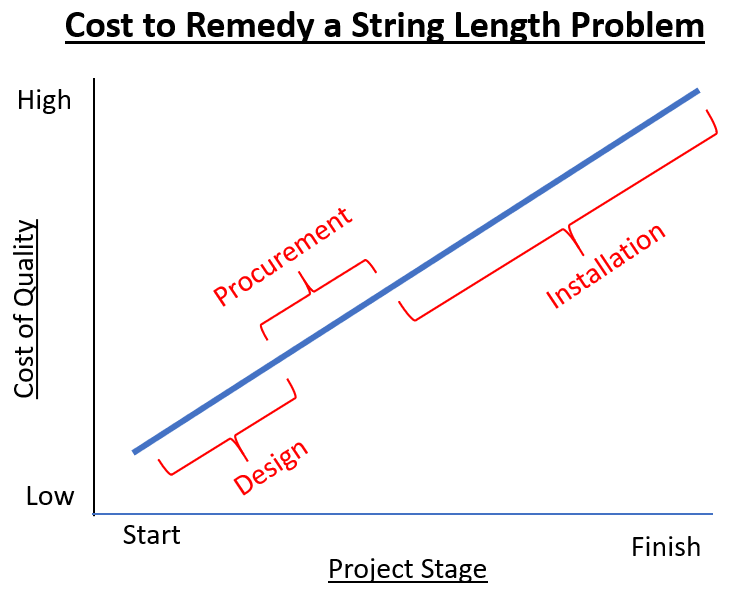

Consider a mistake in voltage calculations leading to an incorrect string length. Depending on when the error is caught, the consequences vary:

1. **Design Phase**: The issue can be corrected by revising the design and racking table. There’s minimal impact on cost or schedule.

2. **Procurement Phase**: If equipment has already been ordered, changing the string length might require reordering inverters or adjusting the layout. This could lead to delays or added costs.

3. **Installation Phase**: Once the system is wired, correcting the string length involves removing and reinstalling conductors. This may require additional jumpers, increasing both time and cost, and potentially affecting long-term operations and maintenance.

As an Independent Engineer (IE), we always aim to preserve quality throughout the project lifecycle. However, when reviews are conducted too late—often at the end of installation—fixing quality issues becomes significantly more costly and time-consuming.

### The Problem with Late IE Reviews

Developers often bring in engineers late in the project to satisfy owners or lenders who want to de-risk the project. This final review is usually done just before handover, as a last check on design and installation.

At this stage, addressing quality issues requires significant changes, which can impact both time and budget. By the time a problem is discovered, many key steps have already been completed:

- Design is finalized

- Materials are procured and installed

- Labor has been expended

- Performance guarantees are set in contracts

This means any corrections will likely lead to delays, increased costs, or suboptimal solutions.

### Example of the Cost of Quality: String Length Miscalculation

Consider a mistake in voltage calculations leading to an incorrect string length. Depending on when the error is caught, the consequences vary:

1. **Design Phase**: The issue can be corrected by revising the design and racking table. There’s minimal impact on cost or schedule.

2. **Procurement Phase**: If equipment has already been ordered, changing the string length might require reordering inverters or adjusting the layout. This could lead to delays or added costs.

3. **Installation Phase**: Once the system is wired, correcting the string length involves removing and reinstalling conductors. This may require additional jumpers, increasing both time and cost, and potentially affecting long-term operations and maintenance.

### Minimizing the Triple Constraints

While the triple constraints of Quality, Time, and Cost remain relevant, the cost of fixing issues increases dramatically depending on when they’re identified.

- **Early IE Review**: Catching problems early allows for quick fixes with minimal impact on cost and schedule. Stakeholders appreciate early input because it leads to better outcomes without major disruptions.

- **Late IE Review**: When reviews happen too late, the cost of remediation is high. Everyone is frustrated, not because the IE found issues, but because fixing them now is expensive and time-consuming.

Some may argue that the EPC should bear the cost of fixes, but even then, all parties face indirect costs like extra meetings, delays, and conflicts over change orders. EPCs may also resist some IE recommendations due to financial pressure, leading to shortcuts or ignored concerns.

### Conclusion

Involving an Independent Engineer early in the project lifecycle adds real value. It helps identify risks, improve design, and ensure quality without unnecessary costs or delays.

The later the IE review, the more it becomes a “check-the-box†exercise, reducing its effectiveness. If you're investing in an IE, make sure to get the most out of their expertise by involving them from the start.

### Minimizing the Triple Constraints

While the triple constraints of Quality, Time, and Cost remain relevant, the cost of fixing issues increases dramatically depending on when they’re identified.

- **Early IE Review**: Catching problems early allows for quick fixes with minimal impact on cost and schedule. Stakeholders appreciate early input because it leads to better outcomes without major disruptions.

- **Late IE Review**: When reviews happen too late, the cost of remediation is high. Everyone is frustrated, not because the IE found issues, but because fixing them now is expensive and time-consuming.

Some may argue that the EPC should bear the cost of fixes, but even then, all parties face indirect costs like extra meetings, delays, and conflicts over change orders. EPCs may also resist some IE recommendations due to financial pressure, leading to shortcuts or ignored concerns.

### Conclusion

Involving an Independent Engineer early in the project lifecycle adds real value. It helps identify risks, improve design, and ensure quality without unnecessary costs or delays.

The later the IE review, the more it becomes a “check-the-box†exercise, reducing its effectiveness. If you're investing in an IE, make sure to get the most out of their expertise by involving them from the start.

Quality in projects is often measured in terms of Time (schedule) and Cost ($$$). Project Management literature refers to these as the “triple constraints,†typically illustrated by the classic triangle:

Quality in projects is often measured in terms of Time (schedule) and Cost ($$$). Project Management literature refers to these as the “triple constraints,†typically illustrated by the classic triangle:

The idea is that you can optimize two of the three constraints but must compromise on the third. In solar projects, this balance between time, cost, and quality is especially critical during design and construction.

The idea is that you can optimize two of the three constraints but must compromise on the third. In solar projects, this balance between time, cost, and quality is especially critical during design and construction.

As an Independent Engineer (IE), we always aim to preserve quality throughout the project lifecycle. However, when reviews are conducted too late—often at the end of installation—fixing quality issues becomes significantly more costly and time-consuming.

### The Problem with Late IE Reviews

Developers often bring in engineers late in the project to satisfy owners or lenders who want to de-risk the project. This final review is usually done just before handover, as a last check on design and installation.

At this stage, addressing quality issues requires significant changes, which can impact both time and budget. By the time a problem is discovered, many key steps have already been completed:

- Design is finalized

- Materials are procured and installed

- Labor has been expended

- Performance guarantees are set in contracts

This means any corrections will likely lead to delays, increased costs, or suboptimal solutions.

### Example of the Cost of Quality: String Length Miscalculation

Consider a mistake in voltage calculations leading to an incorrect string length. Depending on when the error is caught, the consequences vary:

1. **Design Phase**: The issue can be corrected by revising the design and racking table. There’s minimal impact on cost or schedule.

2. **Procurement Phase**: If equipment has already been ordered, changing the string length might require reordering inverters or adjusting the layout. This could lead to delays or added costs.

3. **Installation Phase**: Once the system is wired, correcting the string length involves removing and reinstalling conductors. This may require additional jumpers, increasing both time and cost, and potentially affecting long-term operations and maintenance.

As an Independent Engineer (IE), we always aim to preserve quality throughout the project lifecycle. However, when reviews are conducted too late—often at the end of installation—fixing quality issues becomes significantly more costly and time-consuming.

### The Problem with Late IE Reviews

Developers often bring in engineers late in the project to satisfy owners or lenders who want to de-risk the project. This final review is usually done just before handover, as a last check on design and installation.

At this stage, addressing quality issues requires significant changes, which can impact both time and budget. By the time a problem is discovered, many key steps have already been completed:

- Design is finalized

- Materials are procured and installed

- Labor has been expended

- Performance guarantees are set in contracts

This means any corrections will likely lead to delays, increased costs, or suboptimal solutions.

### Example of the Cost of Quality: String Length Miscalculation

Consider a mistake in voltage calculations leading to an incorrect string length. Depending on when the error is caught, the consequences vary:

1. **Design Phase**: The issue can be corrected by revising the design and racking table. There’s minimal impact on cost or schedule.

2. **Procurement Phase**: If equipment has already been ordered, changing the string length might require reordering inverters or adjusting the layout. This could lead to delays or added costs.

3. **Installation Phase**: Once the system is wired, correcting the string length involves removing and reinstalling conductors. This may require additional jumpers, increasing both time and cost, and potentially affecting long-term operations and maintenance.

### Minimizing the Triple Constraints

While the triple constraints of Quality, Time, and Cost remain relevant, the cost of fixing issues increases dramatically depending on when they’re identified.

- **Early IE Review**: Catching problems early allows for quick fixes with minimal impact on cost and schedule. Stakeholders appreciate early input because it leads to better outcomes without major disruptions.

- **Late IE Review**: When reviews happen too late, the cost of remediation is high. Everyone is frustrated, not because the IE found issues, but because fixing them now is expensive and time-consuming.

Some may argue that the EPC should bear the cost of fixes, but even then, all parties face indirect costs like extra meetings, delays, and conflicts over change orders. EPCs may also resist some IE recommendations due to financial pressure, leading to shortcuts or ignored concerns.

### Conclusion

Involving an Independent Engineer early in the project lifecycle adds real value. It helps identify risks, improve design, and ensure quality without unnecessary costs or delays.

The later the IE review, the more it becomes a “check-the-box†exercise, reducing its effectiveness. If you're investing in an IE, make sure to get the most out of their expertise by involving them from the start.

### Minimizing the Triple Constraints

While the triple constraints of Quality, Time, and Cost remain relevant, the cost of fixing issues increases dramatically depending on when they’re identified.

- **Early IE Review**: Catching problems early allows for quick fixes with minimal impact on cost and schedule. Stakeholders appreciate early input because it leads to better outcomes without major disruptions.

- **Late IE Review**: When reviews happen too late, the cost of remediation is high. Everyone is frustrated, not because the IE found issues, but because fixing them now is expensive and time-consuming.

Some may argue that the EPC should bear the cost of fixes, but even then, all parties face indirect costs like extra meetings, delays, and conflicts over change orders. EPCs may also resist some IE recommendations due to financial pressure, leading to shortcuts or ignored concerns.

### Conclusion

Involving an Independent Engineer early in the project lifecycle adds real value. It helps identify risks, improve design, and ensure quality without unnecessary costs or delays.

The later the IE review, the more it becomes a “check-the-box†exercise, reducing its effectiveness. If you're investing in an IE, make sure to get the most out of their expertise by involving them from the start.Roadking Tyre,Long Life Tires,Seismic Resistant Tires,High Safety Tires

WINMAX AND MACROYAL TYRE GROUP , https://www.glamorcorp.com