How Robotic Welding Scales Production and Grows Your Business

How Robotic Welding Boosts Production and Drives Business Growth

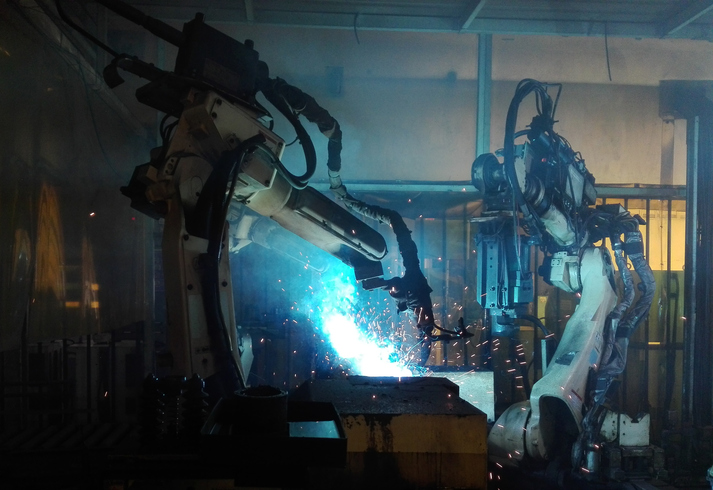

Robotic welding is more than just a cost-saving tool—it's a game-changer for manufacturers looking to scale efficiently and grow sustainably. While labor costs are often the first benefit that comes to mind, the real value lies in how robotic systems enhance safety, quality, and productivity across the board.

Manual welding can be effective for complex or unique parts, but when it comes to repetitive, high-volume welds, it often falls short. These tasks can lead to inconsistencies, delays, and higher long-term costs. That’s where robotic welding steps in, offering a reliable, efficient alternative that transforms the production line.

The Key Benefits of Robotic Welding Over Manual Methods

When comparing robotic welding to traditional methods, several advantages stand out:

- Higher Uptime and Efficiency: Unlike human workers, robots don’t need breaks or rest periods. They operate continuously (except during scheduled maintenance), significantly increasing overall output and reducing downtime.

- Consistent Quality and Precision: Once programmed, robots deliver the same high-quality weld every single time. This level of consistency ensures uniform product quality and reduces the risk of defects.

- Lower Operating Costs: Robotic systems reduce the need for highly skilled labor and minimize material waste. This leads to long-term savings and a faster return on investment.

- Improved Competitive Edge: Companies that adopt robotic welding can produce more, faster, and at a lower cost—making them more attractive to clients and better positioned to win contracts.

These benefits make robotic welding not just an option, but a strategic move for any manufacturer aiming to stay ahead in today’s competitive market.

Driving Business Growth with Automated Welding Solutions

A recent case study from Genesis Systems Group highlights how one company transformed its operations by implementing a custom robotic welding system. The manufacturer, which specialized in metal pallets and skid systems, was struggling with manual processes that couldn’t keep up with demand or meet military-grade standards.

As production demands increased, the manual approach became too slow and inefficient, leading to missed deadlines and unprofitable operations. By integrating robotic welding, the company was able to cut cycle times dramatically, improve quality, and scale production effectively.

This story is just one example of how automation can unlock new growth opportunities. To explore this success in detail, check out the full case study from Genesis Systems Group.

Four- Side Milling Angle Sanding Machine

Four- Side Milling Angle Sander,4 Sides Wood Edge Sanding Machine,Angle Edge Banding Machine,Four-Side Milling Equipment

Foshan Sandwell Machinery Co.,ltd , https://www.sandwellsand.com