Robotic Welding: How Manufacturers Realize ROI, Part 2

Robotic Welding: How Manufacturers Realize ROI, Part 2

Robotic Welding: Boosting Uptime and Achieving 85% Efficiency

Robotic Welding: Boosting Uptime and Achieving 85% Efficiency

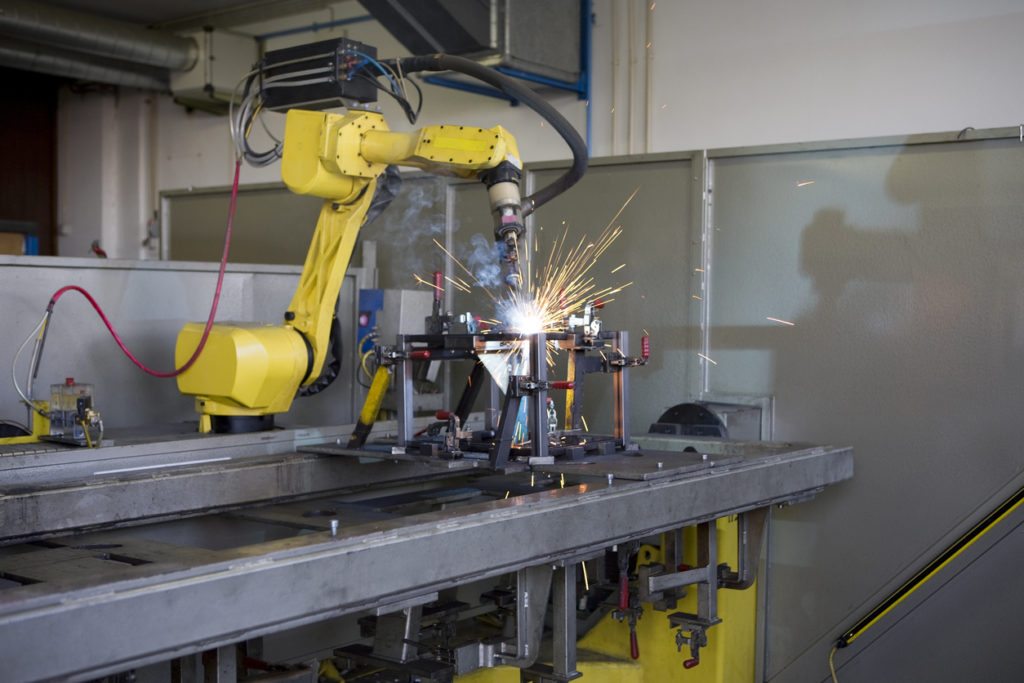

It's a common belief that robots are faster at welding than human workers. However, this isn't always the case. Most robotic systems are designed to replicate the movements of a skilled welder rather than outpace them. The real advantage of robotic welding lies in its ability to maintain consistent uptime, leading to higher productivity and better quality over time.

Manual welding processes typically operate at only around 20% efficiency due to various interruptions. Workers need breaks, have to move between tasks, adjust their positions, or check the quality of their work. These factors significantly reduce the actual time spent on welding, resulting in lower output and increased rework.

In contrast, robotic welding systems can operate continuously with minimal interruptions. Once installed, they can run for years with scheduled maintenance, which helps avoid costly unscheduled downtime. This high level of reliability ensures that more time is spent on actual welding, not on rest or other distractions.

Many robotic welding cells also include additional features like automatic nozzle cleaning stations. These devices help keep the welding gun free from debris, reducing defects and rework. By maintaining clean and precise operations, robotic systems improve both efficiency and product quality.

While robots may not be faster in terms of individual welds, their ability to work consistently and accurately makes them a powerful asset for manufacturers. They don’t get tired, don’t require meals or rest, and can maintain high standards throughout the day. This leads to a significant increase in throughput and overall production quality.

The improved uptime and efficiency offered by robotic welding play a key role in delivering a strong return on investment (ROI) for manufacturers across industries. As we continue our four-part series, next week’s installment will focus on how robotic welding improves labor conditions and workplace safety.

For more insights, read Part 1 of the Robotic Welding Series: Avoiding Rework and Excessive Material Consumption.

Posted in Robotic Weldinghot work tool steel,hot work steels,hot work die steel,hot die steel h13

Jiangyou ChongxinSpecial Metal Materials Co., Ltd. , https://www.zhongxindiesteel.com

The other day, my brother was talking about introducing arc welding robots into the workplace. It's an interesting concept to read about and hear that their efficiency is truly unmatched. Especially when it's pointed out that robots won't tire out like people do. It's fascinating to see how technology continues to reshape traditional manufacturing processes.