Robotic Welding: How Manufacturers Realize ROI, Part 2

Robotic Welding: How Manufacturers Achieve ROI, Part 2

Robotic Welding: Boosting Uptime and Achieving 85% Efficiency

Robotic Welding: Boosting Uptime and Achieving 85% Efficiency

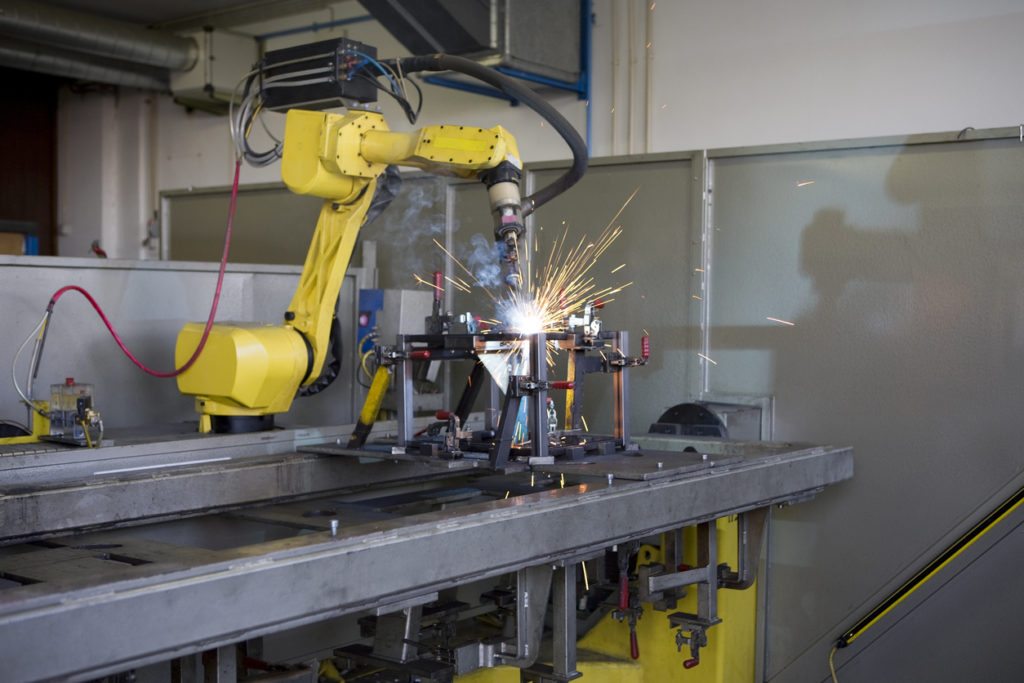

It's a common belief that robots weld faster than humans. However, this is not entirely accurate. Most automated systems are designed to replicate the movements of human welders. The real advantage of robotic welding lies in its ability to maintain higher uptime compared to manual processes. Robots don't get tired, they don’t need breaks, and they can work continuously for extended periods. This leads to greater output, improved quality, and fewer errors—not because they are faster, but because they spend more time welding with consistent precision (see Robotic Welding Series Part 1: Avoiding Rework and Excessive Material Consumption).

Manual Processes Typically Only Reach 20% Efficiency

It might be surprising, but manual welding operations often have very low efficiency. Human workers take breaks, need to move around for materials, adjust their positions, or pause to check quality. These interruptions drastically reduce the amount of actual welding time. As a result, most manual welding processes only achieve about 20% uptime.

Robots, on the other hand, operate without these limitations. They can run continuously, which makes them far more efficient over time.

Robotic Welding Can Achieve Up to 85% Uptime

Once installed, robotic welding systems typically start working immediately and continue operating for years with minimal downtime. The only scheduled maintenance required is for preventive care—something that helps avoid costly unscheduled shutdowns.

Additionally, robotic welding cells can be equipped with various peripherals to further enhance performance. For instance, automatic nozzle cleaning stations ensure that the welding torch remains free from debris between cycles. This reduces defects, rework, and production delays, all of which improve overall efficiency.

When comparing manual and automated welding, it’s important to focus on the significant gains in uptime rather than speed. While robots may not always be faster, their ability to work consistently and accurately over long periods leads to higher throughput and better product quality every day.

Increased uptime and high efficiency are two major reasons why robotic welding delivers strong return on investment for manufacturers across industries.

Stay tuned for part 3 of our four-part series next week: Improving Labor and Workplace Safety.

Robotic Welding Series Part 1: Avoiding Rework and Excessive Material Consumption

Posted in Robotic WeldingPlastic Mould Steel,Plastic Mold Steel

Jiangyou ChongxinSpecial Metal Materials Co., Ltd. , https://www.zhongxindiesteel.com

The other day, my brother was talking about introducing arc welding robots into the workplace. It's an interesting concept to read about and hear that their efficiency is truly unmatched. Especially that it's pointed out that robots won't tire out like people will. I found it fascinating how automation can really transform a manufacturing environment.