Determination of gluten in flour by gluten analyzer

From a series of experiments, it can be seen that among the five methods for determination of wheat gluten, the data measured by the Brabender's small experimental mill method is the closest to the actual gluten value of the flour, so it is the best assay. However, due to Brabender’s small experimental mills being more expensive, this method is difficult to promote. Wheat gluten was measured by the whole wheat flour method. Since the sample used in this method was a whole wheat flour and had a large amount of bran, the difference between the data measured by this method and the flour gluten was greatest. Therefore, the author believes that this method is the most inaccurate and not a very good method of measurement (Note: Nanjing Hengheng Flour Company has always used this method, because the crusher used to crush the sample is an imported crusher, and the price is probably several ten thousand yuan. The renminbi, so the measured value and the flour gluten value difference is not very big, generally lower than the flour gluten 2.0 ~ 2.5). The method for determining wheat gluten which is both economical and practical is the CB30 sieve method and the CB36 sieve method. Of course, the above-mentioned methods for measuring wheat gluten and flour gluten are only suitable for wheat with water content of 12.0% to 13.0%, because if the wheat water content is too low, the wheat bran is crushed when crushed by the JFS experimental mill. The gluten content of the 10g sample is used to determine the gluten content of the gluten and the gluten is not measured. Therefore, the measured wheat gluten is on the low side, and conversely, it is on the high side.

The determination of gluten analyzer must be based on the actual situation in the theoretical calculation process and have the flexibility to grasp the above calculation methods. Only in this way can it play a guiding role in actual production. Calls on the relevant national standard-setting departments to formulate a unified method for determining the national standard of wheat gluten as soon as possible so as to avoid disagreement on the quantity of wheat gluten in the grain-collecting party and the grain-producing party. Trouble.

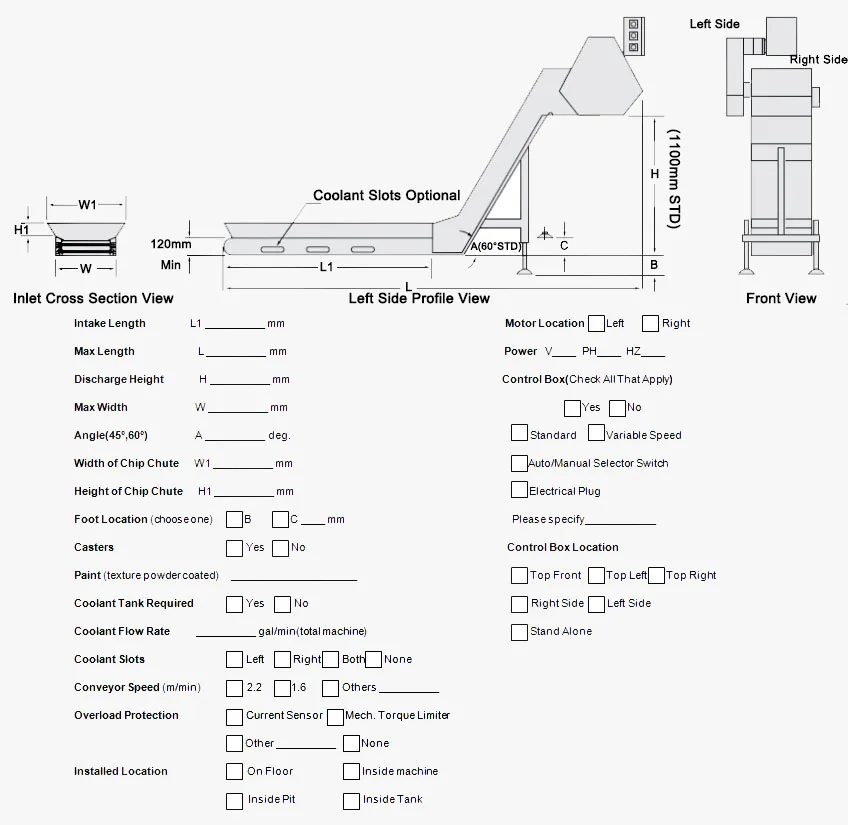

Production Features:

- Chip Conveyor is used primarily in industrial settings to carry away waste, such as chips or the shavings produced during machining and manufacturing operation.

- They are typically small and designed to handle wet or dry waste as many of types of processes that create the waste they are designed to carry use water or other liquids as lubricants.

- They are useful for a number of reasons as they carry waste away from the work area, promoting safety and cleanliness.

- They also aid in recycling processes for scrap and filter chips, shavings and other scrap from lubricating materials, which helps reduce clogging in drains, pipes and tanks.

Product Description:

- Compact with high efficiency , it is the most proper machine model for complying with CNC , NC machine.

- Plural scraped width offers you the optimal application for wide range and the effectiveness.

- Mono-assembly of link plate with high strength, precise coordination and stable /silent motion.

- A design of small GAP convex points is available to prevent the chips from adhering due to the powerful ability on removing the chips.

-

With a limited torque force, it can effectively reduce the damage to the minimum level that caused by improper operation.

FAQ:

What are your advantages?

We perfect every detail. We only supply high quality Chain plate scraped conveyors chip conveyor for cnc machine , and a four-member professional team will be sincerely at your service anytime. All your problems would be very efficiently.

Are you a manufacturer or a distributor?

We are a manufacturer as well as a trading company, so we can ensure , and also we could assist you purchase other products by virtue of our excellent trading power.

Can your send us samples for testing?

Yes, samples in small quantity would be free of charge, but freight should be paid in advance or freight collect. Quality of the products you`ll purchase would be the same as that of samples.

What's your payment terms?

T/T, L/C at sight. Western Union any Paypal are also available if it is convenient for you.

How about the delivery time?

Within 3-7 days for stock goods, 10-25 day for customized products after receiving the prepayment or relevant L/C.

How do you pack the good?

Standard wooden case.

Could you print on the products as per our requests?

Yes,we could print images or words on the products, such as your logo, brand etc, if you buy in bulk.

Scraper Type Chip Conveyor,Scrap Conveyor,Scraped Type Machine Chip Conveyor,Scraping Plate Type Chip Conveyor

Hebei Hosan Machine Equipment Co.,Ltd , http://www.hosanmachinery.com