7 Safety Tips on Operating an Excavator

Excavators are indispensable tools across various industries. Whether you're breaking ground or moving earth, these machines are designed to handle tough jobs effectively. However, they cannot operate autonomously—trained operators are essential for their safe and efficient use. Modern excavators come equipped with advanced safety features, but these don’t eliminate the need for careful handling. Only experienced operators should operate these machines.

Operating an excavator carries inherent risks. To stay safe, follow these seven essential safety tips:

1. Inspect Equipment Basics

Before starting your day, thoroughly examine your equipment. Familiarize yourself with all safety features, including horns, lights, guards, fire extinguishers, windows, and wipers. Ensure the engine and hydraulic fluid levels are adequate. Inspect the boom, stick, and bucket for damage. Check all controls to confirm they are functioning correctly. Look for signs of wear, such as hydraulic leaks, loose bolts, or cracked welds. Regular monthly inspections should include belts, hoses, and drive sprockets.

2. Your Role as an Operator

Safety starts with how you approach your role. Keep the cab tidy—no dirt, grease, or clutter that could interfere with operations. Clean the windshield to enhance visibility and avoid glare. Test all controls before starting work. Grease the bucket hinges as needed, depending on weather conditions and the material being excavated. When entering or exiting the cab, always use the three-point method: keep two hands and a foot or two feet and a hand in contact with the machine. Wear clean footwear to prevent slips, and buckle your seatbelt.

3. Assess the Worksite

Clear the area of hazards like rocks, debris, and stumps. Check for hidden dangers such as holes, ditches, or slopes. If you're working in a new area, consult with the local utility company to mark underground utilities. Contact with live power lines can electrify the excavator, endangering everyone nearby.

4. Fuel Up Before Starting

Running out of fuel mid-operation is dangerous. A sudden stop can cause the bucket or arm to drop, potentially harming nearby workers. Start with a full tank and check engine and hydraulic fluid levels. Low fluids can damage the machine.

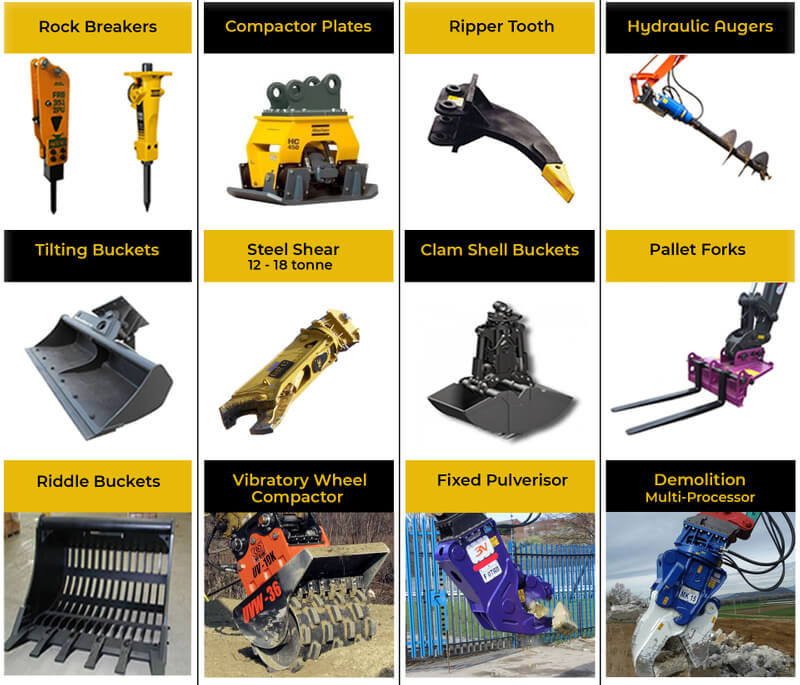

5. Use Proper Attachments

Always use manufacturer-approved attachments. Select the right style and size for your task. Heavy-duty buckets suit most soil types, while severe-duty buckets are ideal for abrasive materials. Never exceed the machine's load capacity. Refer to the operator manual for specifications. Remember that lifting capacity decreases as the bucket rises, so stick within the recommended limits.

6. Navigate Inclines Carefully

Operating on uneven ground requires extra caution. Avoid positioning the tracks parallel to a slope—it’s unstable and risky. Travel straight up slopes, keeping the boom and arm extended and the bucket low. Drive slowly, avoiding sharp turns and sudden stops. Keep the bucket close to the machine and watch for obstacles. Reduce speed in rough areas and park on level ground when idle.

7. Follow Best Practices

Avoid operating if tired or stressed from extreme temperatures. Never let unauthorized personnel near the machine. Ensure everyone working nearby is aware of the excavator’s movements. Operators might not see everyone at once, so communication is key. Wear appropriate attire and protective gear. Face the machine when climbing on or off.

By adhering to these guidelines, you can prevent accidents, injuries, and costly damages. These principles are crucial for responsible excavator operation.

RENT EXCAVATOR

We, Antbuildz.com, are Singapore’s premier digital equipment rental platform. We’re transforming traditional rentals into a seamless, touch-free experience. Visit antbuildz.com to browse equipment like push-around lifts, boom lifts, generators, or scissor lifts. Compare prices and book instantly. Don't forget to like and share our Facebook page! bit.ly/34MdSFh

Potato Peeler Machine,Fruit Peeling Machine,Potato Washing And Peeling Machine,Vegetable Peeling Machine,Coconut Peeling Machine

Guangzhou Shengtian Machinery Co. LTD , https://www.stfoodmachinery.com