Biscuit Metal Detection Machine (MDC-B)

Model NO.: MDC-B

FEATURES

This advanced metal detection system is designed to automatically adapt to various product effects, ensuring high accuracy in detecting even the smallest metallic contaminants. It utilizes all-digital signal processing and transmission technology, providing high sensitivity and excellent reliability. Powered by a 32-bit high-speed CPU, it offers precise control and real-time performance. The dual LED display clearly indicates the sensitivity levels of both ferrous and non-ferrous metals, allowing for individual adjustment of detection settings. Optional reject systems are available to suit different production line requirements. The unit features a high protection rating and an adjustable height frame, making it suitable for a wide range of applications.

PURPOSE

This system is ideal for online metal detection in food products, serving as a critical step in maintaining food safety, especially under HACCP guidelines. It can also be used for detecting metallic contaminants in chemical and rubber products, offering versatility across multiple industries.

SPECIFICATIONS

- **Technology**: Balanced Coil

- **Adjustment**: Auto-adjust, with separate controls for ferrous and non-ferrous sensitivity

- **Aperture Size**: 600 x 80 mm (standard)

- **Alarm System**: Buzzer and visual lamp

- **Reject Options**: Air blast, air pusher, or swing arm (optional)

- **Belt Speed**: 25–32 m/min (adjustable)

- **Power Supply**: AC 110V / 220V, 50–60Hz

- **Rated Output**: Approximately 140W

- **Dimensions**: 1620 mm (L) x 1000 mm (W) x 1100 mm ± 50 mm (H)

- **Weight**: Approximately 200 kg

SERIES

| Aperture Size | Ferrous (Fe) | Stainless Steel (SUS) |

|---------------|--------------|------------------------|

| 600mm x 80mm | 0.8mm | 1.2mm |

| 600mm x 100mm | 1.0mm | 1.5mm |

| 600mm x 120mm | 1.0mm | 2.0mm |

| 600mm x 150mm | 1.2mm | 2.5mm |

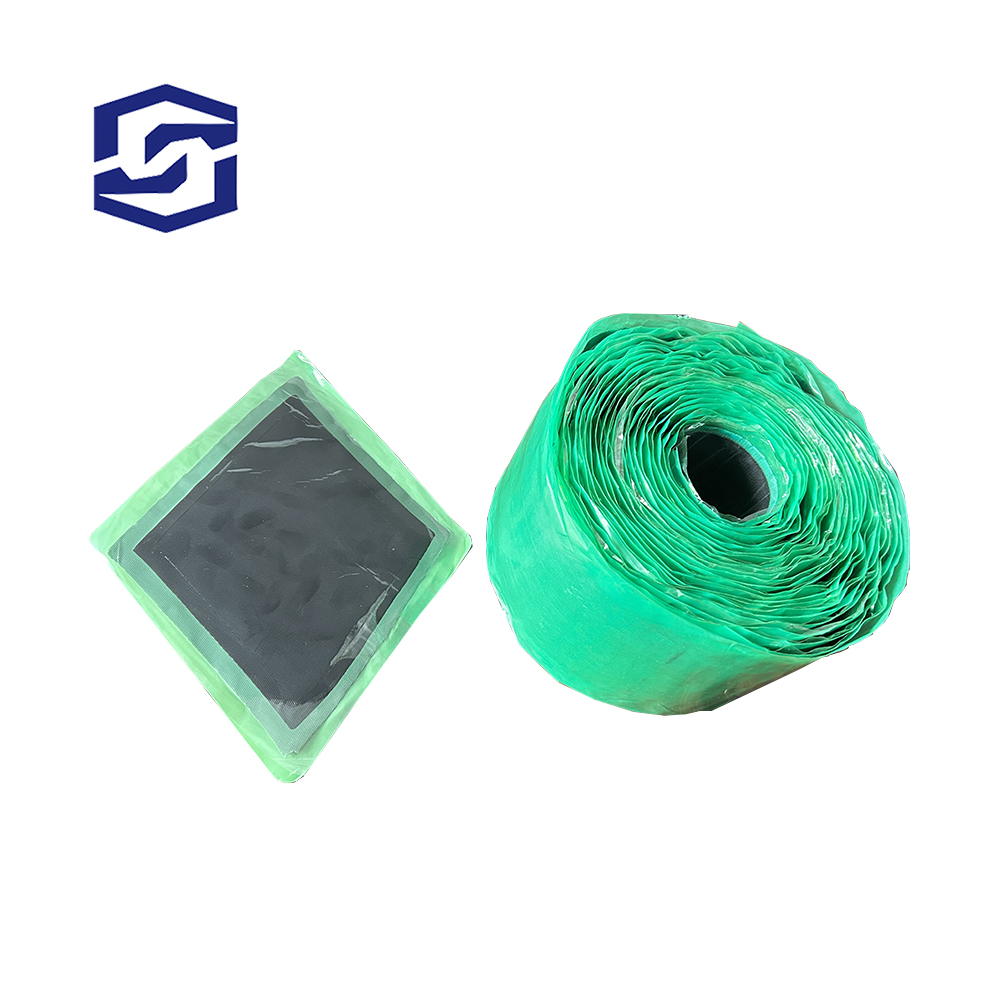

This model is perfect for manufacturers looking for a reliable, efficient, and flexible solution for metal detection in their production lines. Its advanced features and customizable options make it a top choice for ensuring product quality and compliance with industry standards.SL rubber repair series products are widely used, mainly used for rubber products and polyurethane and other elastomer damage repair.

Â

Such as: repair of various damage of conveyor belt, repair of wear resistant pipe lining damage, sealing of conveyor belt joints, cold patching of cables, coating of turbine blades, protection of belt buckles, and other kinds of rubber products.

Â

rubber repair,repair strip,conveyor belt repair strip,conveyor belt rubber repair,patch

Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com