Utilizing Moldex3D CADdoctor to Easily Fix Geometric Errors & Ensure High-Quality Mesh Generation

Having a good quality geometry is essential in building a proper mesh for a successful CAE analysis. Low-quality geometry will need additional manual efforts to repair defects in the pre-processing stage and the mesh quality can be compromised.

Moldex3D CADdoctor is a useful tool that supports data translation among multi-CAD systems and fixes geometric errors from different file conversions.

Here are 3 easy steps in CADdoctor to help you check and fix common errors of your CAD model:

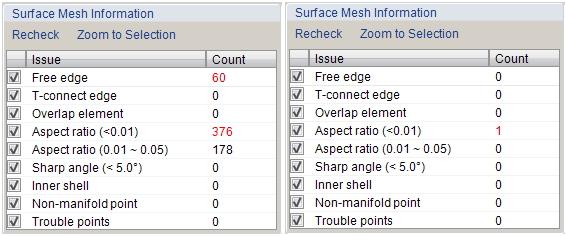

Surface mesh defect: Not using CADdoctor (left) vs. using CADdoctor (right)

Surface mesh defect: Not using CADdoctor (left) vs. using CADdoctor (right)

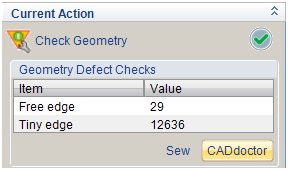

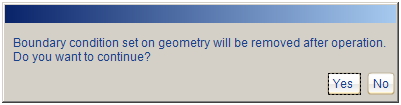

Step 1: After importing the geometry into Designer, click ![]()  to review the geometry quality. Under Geometry Defect Checks, click CADdoctor and select Yes in the following window. CADdoctor will be launched and the model will be imported automatically.

to review the geometry quality. Under Geometry Defect Checks, click CADdoctor and select Yes in the following window. CADdoctor will be launched and the model will be imported automatically.

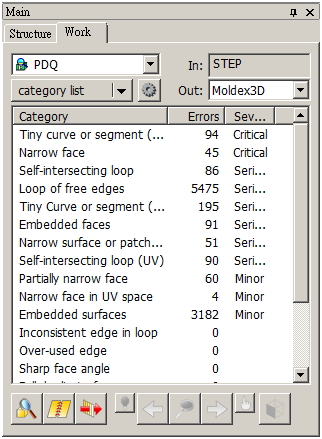

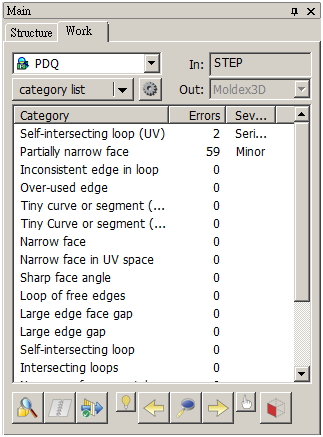

Step 2: The main working panel on the left has two sections: the upper section lists all the detected

defects, and the lower section contains the basic repair tools (![]() ). First, click

). First, click![]() Â to Check the geometry defects and the results will be listed in the table.

to Check the geometry defects and the results will be listed in the table.

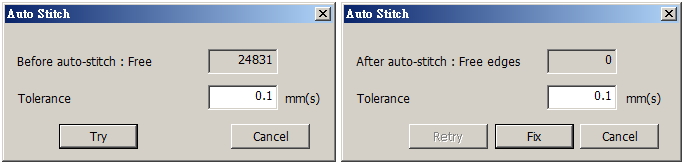

Step 3: Second, click ![]()  Auto Stitch to fix adjacent vertexes and curves with distance smaller than the user-defined tolerance. The pop-up window will show the number of free edges before auto-stitch and the tolerance to apply.  Specify a tolerance and click Try; CADdoctor will estimate the number of free edges after stitch. Click Fix to execute stitching if satisfied with the estimated result.

Auto Stitch to fix adjacent vertexes and curves with distance smaller than the user-defined tolerance. The pop-up window will show the number of free edges before auto-stitch and the tolerance to apply.  Specify a tolerance and click Try; CADdoctor will estimate the number of free edges after stitch. Click Fix to execute stitching if satisfied with the estimated result.

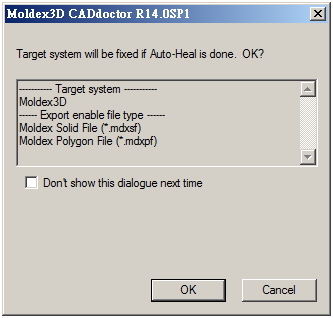

Step 4: Click ![]()  Auto Heal and OK to further improve geometry quality by repairing more geometry defects. After these three basic steps, a significant improvement can be observed in the defect list (the

Auto Heal and OK to further improve geometry quality by repairing more geometry defects. After these three basic steps, a significant improvement can be observed in the defect list (the

Auto Heal icon will then become ![]()  , meaning the model has been improved). User can export the

, meaning the model has been improved). User can export the

modified geometry back to Designer by clicking ![]() Â .

.

Note: Click on the remaining defects, CADdoctor will locate them and suggest corresponding fix tools below the working panel.

Pillar Drill Machine,Drill Tap,Table Drill Machine,Industrial Pillar Drill

Zigong Yibaijie , https://www.oz-yibaijie.com